Partner Products

Supplying the Backbone of Industries, Building Progress

BMA Sugar Engineering And Processing Equipment

Drum Dryer

When drying sugar crystals it is important that the syrup clinging to the crystal surface also undergoes crystallization. This process takes both time and crystal nuclei.

Fluidized bed cooler

For machinery, individual process steps or entire factories – whenever it comeand continuous centrifugals, BMA has been successful across the globe and across sectors.

Drying and cooling combined

By combining a drum dryer with a fluidized-bed cooler, the advantages of both systems complement each other. The result is a design that is highly attractive in terms of energy efficiency and offers an excellent solution, no matter whether it is used for new plants or for expansion programmes.

Batch centrifugal E series

Centrifugals are the most dynamic type of machinery used in sugar production. At high rotational speeds, the sugar crystals are separated from the mother liquor. In the design of our centrifugals, our top priorities are excellent performance, as well as a long service life and outstanding reliability.

K3080 continuous centrifugal

Meet the new addition to our product range of continuous centrifugals machine: the K3080. It has excellent DNA: with more than 500 centtrifugal machines commissioned since 2008, the continuous centrifugal K3 series has been setting new standards in centrifugal design.

K3300F continuous centrifugal

The implementation of continuous processes in production is one factor that ensures efficiency. In sugar production, the continuous centrifugals from BMA ensure continued output coupled with maximum throughput. And even more. Another asset of our centrifugals is their outstanding user-friendliness.

Pan seeding systems

When slurry is used as seed for pan boiling, the technological and economic demand that the product crystallizate be low in aggregates and free of fine crystals cannot be met.

Batch pans

Experience gathered in more than one hundred years in the design and construction of batch pans and know-how acquired from vertical continuous pans (VKT) now determine the design of modern pans.

Slurry mills

Especially for seeding as a preliminary stage of product crystallization proper, the use of a slurry suspension is now state of the art. BMA’s supply line of crystallization equipment also includes a slurry mill operating by the ball mill principle, using hardened steel pebbles.

Cooling Crystalisers

A new generation of efficient coolers. Perfectly equipped for constant crystal growth and maximum yield.

Molasses/massecuite mingler

The BMA massecuite mixer permits optimum mixing of heated molasses and cooling massecuite. Reducing the crystal content and raising the product temperature diminishes the viscosity of the massecuite, subject to requirements, by up to 1/5 of the original figure.

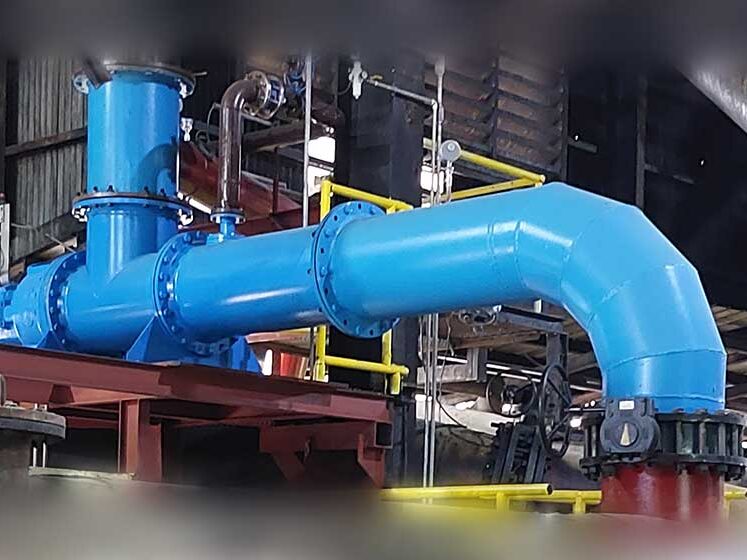

Massecuite pumps

After many months of development, BMA will be presenting a new generation of massecuite pumps in summer 2018: the DRP series. Like its predecessor, the new series has been designed entirely with the requirements of the sugar industry in mind.

Vertical continuous pans

were developed to ensure maximum exhaustion or crystal content for a wide range of massecuite purities in the beet and cane sugar factories and sugar refineries. To date, VKT have been installed in more than 75 factories, meeting very high requirements: process continuity, massecuite with a high crystal content, and a small footprint for outside installation.

Falling-film evaporators

The way an evaporator plant works has a crucial impact on the heat economy of sugar factories and refineries. Perfectly tailored to the overall process, it allows effective action to increase the energy efficiency of upstream or downstream process steps.

WVT Fluidized bed system

Fluidised-bed steam dryers (WVT) from BMA dry the pressed pulp produced in beet sugar factories to obtain a dry substance content of about 90 %. Use of a WVT can also make ecological sense with other types of biomass.

Sugar cane extraction plant

Every sugar campaign aims for maximum output. All the better, if a simple but reliable process can be used already at the juice extraction stage: diffusion. In many up-to-date sugar factories, diffusers from BMA are therefore the state of the art.